Private label

Being specialized in the realization of private labels, our products are also among the best quality watches you could imagine for corporate gifts.

DIFFERENT WAYS TO REALIZE YOUR WATCHES

121TIME and his team has already been involved in several successful partnerships for the production of Private label watches. We propose 2 approaches to launch/develop a Private Label:

-

One is to simply start with a collection based on the 121Time brand portfolio

Which is rapid and convenient. Basically by stamping a logo on existing dials, - or producing a new dial design to fit one of our case (collection). If every watch part is in our stock, a delivery in 3 or 4 weeks is possible.

-

Other way is to consequently start your own development from scratch and we realize your design.

The minimum order quantity (MOQ) to create a watch case from scratch is 300 items for Swiss Made watches (with a cost coverage for 200 blanks cases) and 500 for watches with Japanese movement. Most of target prices can be reached when we start a new project.

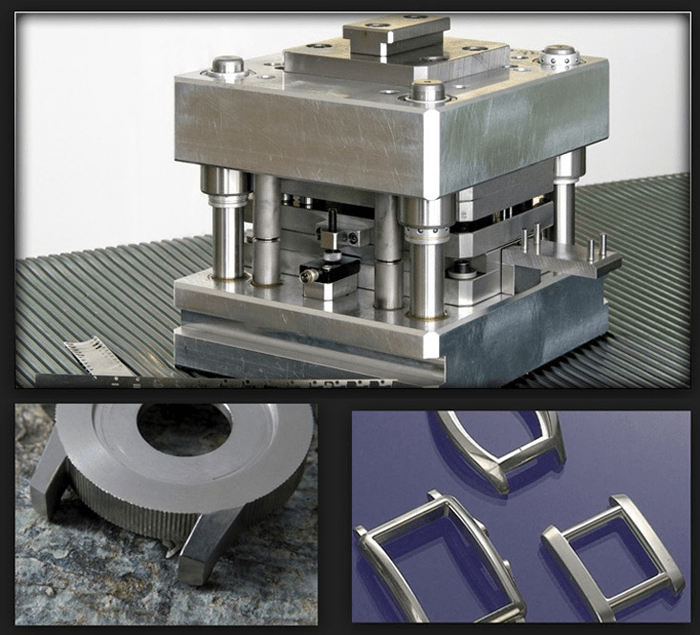

Tooling

When we create a new case, first a tooling is created, then we stamp a piece of steel to give it its final shape (blank case) and then the case is finished by CNC machine and manual polishing.

Different executions of dials, hands, straps are possible for a same case, like different finishes for the case itself: various coating (Gold or black PVD), chrono or classical execution.

In this example, all the cases are issued from the same tooling (moulding) and have a different finish.

-

We can also create a new cases by CNC machine only

The minium order quantity is 100 cases and the unit price more expensive than if made by tooling (with MOQ 300 items). Again we can finish the cases in chronograph or classical execution and make various coating on them. A good approach for higher-end timepieces with mechanical movements.

Made by CNC machines, a complex case with different diamonds and sapphire configuration setting. Blue Sapphires Swiss Made setting in Geneva. Made by CNC machines, a complex case with different diamonds and sapphire configuration setting. Blue Sapphires Swiss Made setting in Geneva. Made by CNC machines, a complex case with different diamonds and sapphire configuration setting. Top Wesselton diamonds Swiss Made setting in Geneva. Made by CNC machines, a complex case with different diamonds and/or sapphire setting. Swiss Made setting in Geneva.

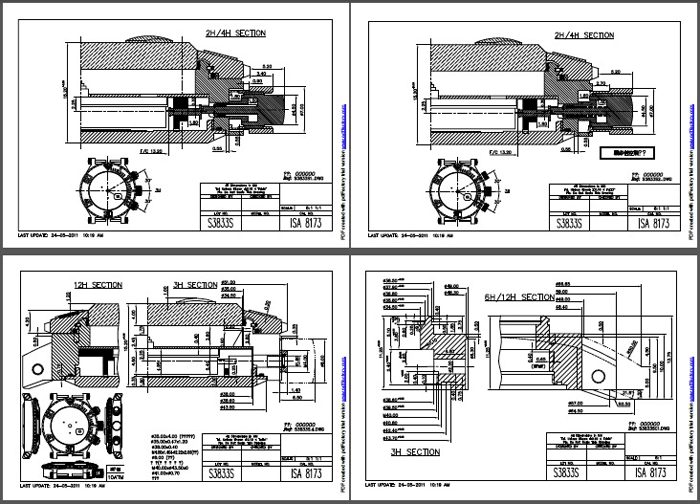

Please be aware that the development of a new watch is an important and a difficult process. The technical drawing for a new case requires usually between 10 and 15 pages made by a certified engineer. Then a tooling must be created according to these plans. The minimum quantity to have the best possible price is 300 items. Lower quantities for a new case model will make the price by unit more important!

TOP CLIENTS

121TIME realizes the watches of several watch brands and has been chosen by top companies to carry their image, including: Hewlett Packard, Medtronic, Mercedes, BMW, Coca-Cola, ABB, Relais Chateaux, US Navy, Swiss Private Banks and many others.

WHAT MAKES US DIFFERENT

Benefit from the expertise gained through the development of the Swiss Made brand 121TIME. You are in direct relation with our manufacturer and therefore benefit from:

- Advice from certified watchmakers located in Switzerland

- Factory price and Swiss Made quality 30 days lead time on average to complete an order when all part are in our stocks